In this article, Woodward Group shares the benefits of having an established process control system and breaks down what you need to know to integrate process engineering into your business.

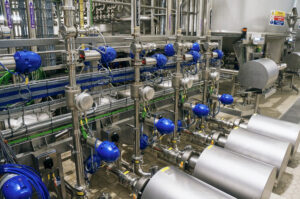

During production, factors such as the temperature, ratios and pressures that raw materials experience can significantly affect the quality of the product, leading to a sub-standard result. That’s why having a suitable process control system can help manage your production line, minimising variables, leading to a satisfactory product. This is even more essential for businesses in industries such as manufacturing – where high-quality products need to be consistently and regularly produced – to save time and money.

Process engineering comes with a number of benefits, including:

A safer work environment. Manufacturing often requires exposure to hazardous materials or dangerous working environments that threaten the safety of employees. Variables such as airflow, turbulence, temperature, fluid pressure, exhaust, and many more can create hazards in the workplace if not adequately controlled. By implementing a process control system, your business can minimise and manage these variables to maximise the safety and productivity of your team.

It can be implemented into almost any business. Since the process control industry encompasses many industries, process engineering can be easily implemented in your business, offering solutions that range from general to bespoke. Process engineering can provide solutions that cover a wide range of variables, such as:

- Temperature;

- Flow;

- Vibration;

- Pressure; and

- Electrical connections.

Not only that, a process control system can provide you with analytics that can help increase efficiency in your production.

It allows you to automate your production line. Since many processes in mass production require precise variable control, a process control system enables a great degree of automation. In addition, a small team of personnel can oversee and operate most of your production line through a central control room.

It streamlines processes, conserving energy and resources. Process engineering provides valuable analytics and data about your production line. This makes it easy to implement efficient adjustments, ensures quality products are consistently made, and minimises resources needed in quality control processes, not to mention the materials wasted on producing faulty products.

At Woodward Group, we take pride in delivering personalised business solutions and a reliable service to our clients. We’re experts in designing and manufacturing high-quality, easy-to-operate industrial control systems for businesses that require innovative solutions.

If your business requires a process engineered solution, or an update for your current system, you can book a free consultation with us by calling 01283 819379 or emailing [email protected]. Woodward Group offers a full range of services, from consultation to implementation and maintenance, tailored to your specific business needs.